REQUEST

Important railway line: Key national 2 tracks line with high rate > 150 trains/day

Over 22 km (14 miles) of non identified sinkholes and weak zones under the track

1 cargo train derailment due to subsidence

Customer ruled out the option of blind drilling and cementation option at cost ~500k$ per 100 linear meters/yards with no guaranty of results, due to the extreme length of the area and unknown positions.

SOLUTIONS

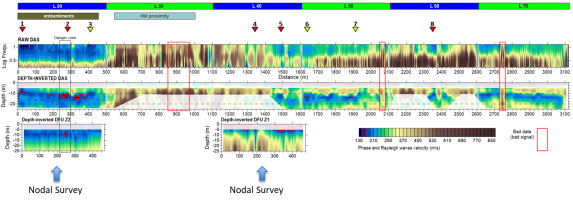

- Initial Wing nodal survey over 2 x 500 meters (1640 ft) and then fiber optic survey over 3 km (10,000 feet) to identify and cure the zones of danger.

- 2 lines of nodal sensors 3 feet apart

- 16 hours of monitoring

- 3 hours to deploy, 2 hours to pick up sensors

- Imaging in 3D with resolution of 1-2 m ( 3-6 ft) with a depth coverage about 1 to 150 m (3-492 ft)

- Cost effective with minimal human intervention.

- 3000 m (10000 feet) of Distributed Acoustic Sensing monitoring during 4 hours. Objectives: identify risk zones for confirmation and remediation works

CONCLUSION

DAS (Distributed Acoustic Sensing) is giving on a long distance a first estimation of potential cavities that will be refined by nodal survey.

Clear identification of risk areas