It’s a monumental task, especially as the industry also faces a shortage of experienced crew members.

Fortunately, innovation isn't just keeping pace; it's accelerating.

A wave of new technologies is reshaping field operations, making them more efficient, insightful, and adaptable. For geophysicists and operations managers, the challenge is knowing where to focus. Here are the seismic tools and trends you should be watching as we head into 2025.

The data revolution: seeing more, and seeing better

The pursuit of clearer subsurface images is driving a fundamental shift in survey design. The move toward higher trace densities is undeniable, with teams leveraging higher source and receiver point densities to create "carpet" style acquisitions. But this isn't just about more points; it's about the quality of those points.

This is where low-frequency imaging with MEMS-based nodal systems comes into play. MEMS (Micro-Electro-Mechanical Systems) sensors have become the go-to solution for capturing stable, reliable data at ultra-low frequencies (below 1.5 Hz). This was once considered noise, but it's now a critical component for deeper exploration, subsalt imaging, and enabling advanced workflows like Full-Waveform Inversion (FWI). Unlike traditional geophones, MEMS sensors offer robust, consistent output, unlocking new depths and helping teams image what was previously hidden.

But how do you manage this data flood? The answer lies in AI-supported QC and processing. Manual, record-by-record QC is no longer feasible with high-density surveys. Smart systems are stepping in, using AI and machine learning for everything from error detection to recognizing acquisition footprints. Technologies like edge computing enable instant processing in the field, while smart nodal QC networks that self-calibrate and repair are becoming the gold standard for delivering confidence without the high cost of traditional “QC at the box” methods.

Leaner operations: automation takes the wheel

As data acquisition becomes more complex, field operations are becoming smarter and leaner, thanks to automation. The optimization of the survey source path is a prime example. Instead of relying on a driver's judgment, automated optimization tools are now choosing the most efficient routes, reducing drive times, fuel costs, and human error.

This automation extends to the vibration cycle itself, with mobile shakers (vibrators) now operating with higher productivity and more precise positioning. The overall impact is profound: less reliance on declining field expertise, reduced safety exposure for crews, lower operational costs, and streamlined performance from start to finish. While the industry is seeing a major nodal shift from cabled to wireless for its flexibility, automation is making both system types more powerful and efficient than ever before.

A sustainable future: new markets, new mandates

Beyond efficiency, technology is enabling seismic acquisition to meet the critical demands of sustainability and the energy transition. Survey designs are increasingly focused on reducing environmental impact through lighter equipment and energy-efficient technologies, like the Intelligent Power Management (IPM) systems found in modern vibrators that significantly cut fuel consumption.

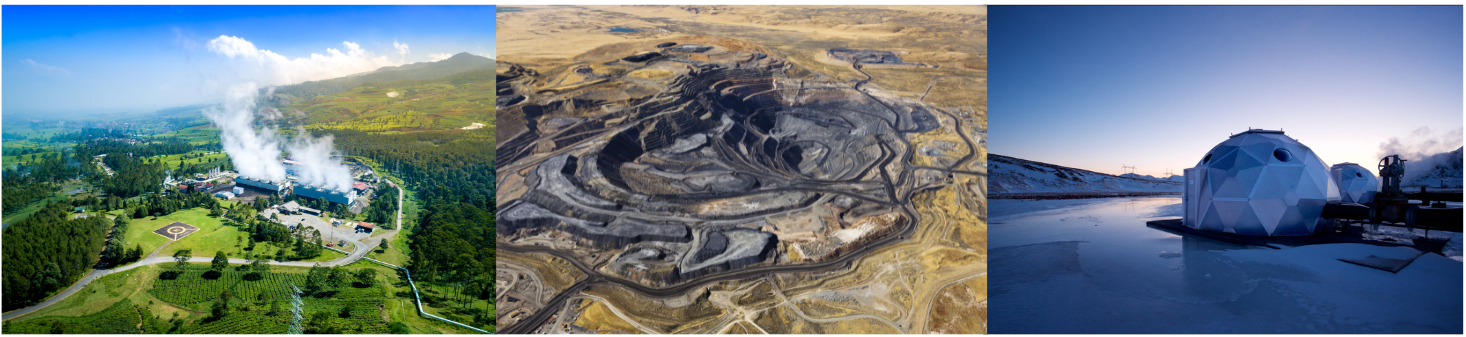

This focus on sustainability is perfectly timed, as the applications for seismic data are rapidly expanding. Seismic acquisition is no longer just for oil and gas. It is a critical tool for geothermal exploration, CO2 storage and monitoring (CCS), the detection of critical minerals, and natural H2 detection systems. These new markets require the high-quality, multi-component data that modern systems are designed to deliver.

Prepare for what's coming next

The future of seismic acquisition is interconnected. Higher-density surveys are made possible by MEMS nodes, which generate data volumes that necessitate AI-powered QC, all while automation drives the efficiency needed to make it commercially viable.

To help you connect the dots and prepare for these changes, we’ve published a comprehensive report detailing the 10 key trends shaping the industry.

Download your free copy of From Cables to Cloud: 10 Game-Changing Trends for Seismic Field Teams to explore what each trend means in practice and how you can leverage these new opportunities to stay ahead.