While the fundamental principles of Vibroseis have remained a cornerstone of land seismic acquisition, the operational reality is undergoing a radical transformation, driven by one powerful force: automation.

The industry is moving beyond incremental improvements. We are now in an era where digital technologies are not just assisting operations but fundamentally redefining them. This shift is turning the once-arduous task of acquiring high-resolution data in different environments into a smarter, safer, and dramatically more productive endeavor.

Beyond the brawn: it’s about the brains

The true revolution in modern source management isn’t just about building more powerful vibrators; it’s about embedding them with intelligence. The latest advancements are tackling the most significant sources of inefficiency and inconsistency head-on.

One of the most impactful developments is vibrator auto-guidance. Historically, the time spent traveling between vibration points (VPs) and accurately positioning the baseplate was subject to driver skill, fatigue, and terrain variability. As our latest white paper, Source Management in the Modern Era, details, auto-guidance automates these steps. By optimizing deceleration and automatically managing baseplate lowering, this technology removes performance uncertainties. The results are striking: productivity enhancements of up to 10% from optimized travel time, coupled with positioning accuracy within a 1-meter radius. This not only delivers better data but also improves safety by managing speed and reducing driver fatigue.

From A-to-B to A-to-Z: the power of path optimization

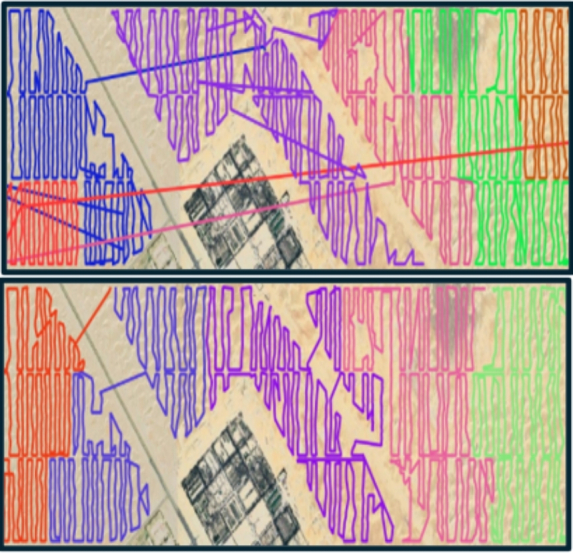

Auto-guidance is just the beginning. The next leap forward is in optimizing the entire production path for a fleet of vibrators. Instead of manually following a predefined route, advanced software can now survey and model project terrain, classifying areas by their level of difficulty.

This allows for the automatic calculation of the most efficient route for the entire fleet, smoothing out shooting operations and leveling performance variations linked to driver skill. The impact on the bottom line is significant. As our research shows, vibrator path optimization can reduce source travel time by up to 20% compared to conventional guidance. In a large-scale survey, that translates to massive savings in time, fuel, and operational costs.

Smarter shooting leads to cleaner signals

The wave of automation extends to the very strategy of data acquisition itself. New decentralized source control methods, like Sercel’s xDSS, are streamlining the source cycle by minimizing the radio communications that have long been a bottleneck. By removing the dependency on firing orders and source-ready messages, xDSS enables crews to achieve record-breaking productivity - reaching over 45,000 VPs per day in some cases - without compromising data quality.

And that quality is also getting an automated boost. Technologies like SmartLF are now embedded directly into vibrator electronics to tackle the challenge of low-frequency harmonic distortion. By using a sophisticated model to predict and correct the vibrator’s intrinsic behavior, SmartLF delivers a cleaner signal at low frequencies, which is essential for high-quality vertical resolution and signal penetration.

Explore the future of source management

These advancements represent a paradigm shift in land seismic operations. Automation is no longer a futuristic concept; it is a suite of practical, field-proven tools delivering tangible benefits today.

To fully grasp the impact of these technologies on your operations, we invite you to download our comprehensive white paper, Source Management in the Modern Era.

Download your free copy today and learn how to leverage the power of automation to make your next seismic survey smarter, cheaper, and more productive.

This in-depth guide explores:

- The evolution of Vibroseis technology from the 1980s to today.

- Detailed analysis of vibrator auto-guidance, path optimization, and advanced shooting strategies like xDSS.

- How digital monitoring and technologies like SmartLF are enhancing both productivity and data quality.